The A1 Difference

Keeping your system running is essential to your business. A1’s proven inspection process and online inspection reports provide you with the best inspection service.

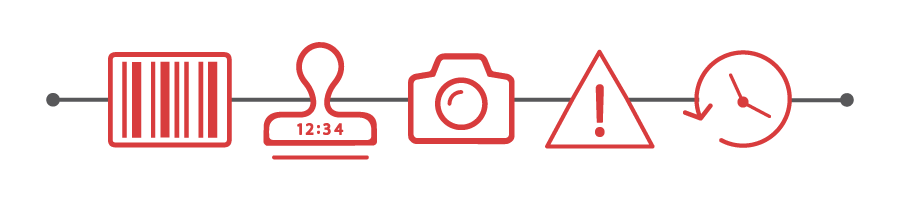

The Process

- All devices are barcoded, labeled, & scanned.

- The scan is logged with a date and time stamp.

- Digital pictures are taken of the before (Open) and after (Closed) state.

- The device is checked against the product recall database.

- The report is available online 24/7/365.

Benefits

- Accurately tracks all devices in your facility

- Ensures all devices are inspected.

- Protects against recalls.

- Easy Accessibility 24/7/365.

- 10% discount with a 6-year agreement.

Fire Alarm

Fire Alarm inspections are prone to errors given the sheer number of devices.

Required

Functional Test

Annual

Battery replacement:

Every 5 years

Sensitivity testing on detectors:

1, 2, & 5 years

Recommended

Battery replacement:

Every 2 years

Smoke/duct detector replacement:

Every 10 years

Recommended sensitivity testing of smoke detectors:

Every 3 years

Fire Extinguishers

Fire extinguishers are a fast and easy method to fight small and non-spreading fires. It is critical to have them operating to prevent small fires from quickly growing out of control.

Required

Visual inspection:

Monthly

Hydrostatic testing (carbon dioxide, wet chemical and pressurized water):

Every 5 years

6 Year maintenance

Hydrostatic testing (dry chemical and clean agent):

Every 12 years

Fire Sprinklers

Wet

A wet pipe sprinkler system employing automatic sprinkler heads attached to a piping system containing water and connected to a water supply so that water discharges immediately from sprinklers opened by heat from a fire.

Annually

Riser or pump room temperature is above 40

Hangers/seismic bracing (from floor level)

Pipe and fittings (from floor level)

Installed sprinklers (from floor level)

Spare sprinklers in spare head cabinet

Information signs

Hose connections/valves (if applicable)

Water flow alarm device is free of physical damage

Supervisory alarm/signal device free of physical damage

Hydraulic nameplate

Pressure reducing and relief valves (if applicable)

Fire department connection (FDC)

Gauges

Alarm valves (exterior)

All valves open and free of damage

Pressure relief and circulation relief valves

Water flow alarm test

Main drain test

Control valve

Anti-freeze solution (if applicable)

Control valve supervisory

Receipt of signal to monitoring service

Semi-Annually

Water flow alarm device free of physical damage

Supervisory alarm/signal device free of physical damage

Hydraulic nameplate

All valves, including hose valves, open and free of damage

Pressure reducing and relief valves

Gauges

Fire department connection (FDC)

Main drain test

Water flow alarm

Control valve supervisory

Quarterly

DRY, PREACTION, DELUGE

A dry pipe sprinkler system is filled with pressurized air. Dry pipe sprinkler systems are installed in areas where wet pipe systems may be inappropriate, such as areas where freezing temperatures might be expected.

Annually

Inspect all gauges

Inspect all sprinkler heads

Inspect all piping and fittings

Inspect hangers and seismic bracing

Inspect spare head box

Operate every control valve

A flow test is conducted at each riser

Partial flow drip test is performed

Obstruction investigation (repairs > 20 sprinklers)

Semi-Annually

Riser or pump room temperature is above 40

Water flow alarm device free of physical damage

Supervisory alarm/signal device free of physical damage

Hydraulic nameplate

Exterior valve

Exterior quick opening device

All valves, including hose valves, open and free of damage

Gauges

Fire department connection (FDC)

Dry valve priming water

Test quick opening device

Main drain test

Water flow alarm

Low pressure alarm

Drain drum drips

Control valve supervisory

Quarterly

Exit & Emergency Lights

Exit and Emergency Lights are a first line of defense in emergency situations. Most buildings still utilize incandescent lamp technology which is maintenance intensive and prone to failure. Regular inspections are necessary to ensure optimal performance in an emergency situation.

Warning: A1 does not recommend a push button test. The residual voltage in the batteries may be enough to run the quick button test but may not be enough to operate in an emergency.

Required

30 second quick check & battery check:

Monthly

90 min functional test, verification of charge voltage, alignment of heads, hazard assessment, inspection sticker, & report:

Annually

Recommended

Battery replacement recommended:

Every 2 years

Evaluate LED or Photoluminescence options:

Fast ROI

Kitchen Hoods

Kitchen Hood systems are one of the most widely used fire protection systems given the fire source and fuel load. Additionally, the environment makes these systems prone to damage and residue build-up, which require increased maintenance.

Required

Functional Test:

Semi-Annually

Change Fusible Links:

Semi-Annually

Test for required cleaning (NFPA 96):

Semi-Annually

Hydrostatic testing of cylinder, replace cartridge, regulator test of wet chemical containers, hose assemblies:

Every 12 Years

Kitchen Exhaust Cleaning

A1 service techs will remove all soiled filters from your exhaust system and replace them with clean filters as well as cleaning the soiled filters. By cleaning the filters off site, your facility will lower the amount of grease going down your drain by up to 70%. This service will reduce labor, electric, water, and chemical expenses while reducing your exposure to fires and EPA fines.

Required

Solid fuel (wood, charcoal):

Monthly

High volume, 24 hour operations, charbroiling, wok cooking:

Every 3 months

Systems serving moderate volume cooking operations:

Every 6 months

Systems serving low-volume cooking operations, such as churches, day camps, seasonal buisiness, or senior centers:

Anually

Filter Maintenance

Kitchen Hood systems are one of the most widely used fire protection systems given the fire source and fuel load. Additionally, the environment makes these systems prone to damage and residue build-up, which require increased maintenance.

Every 6 Months

Replace all soiled grease filters with clean filters, clean and service all filters

Aerosol Suppression

Aerosol fire suppresion systems are a particle-based form of suppression that employs an extinguishing agent consisting of very fine solid particles and gaseous matter, therefore it leaves very little residue in the affected area. This is one of the most efficient forms of suppression.

Required

Functionality testing:

Every 6 months

Inspect enclosure for dramatic changes in leakage:

Annually

Sensitivity testing on detectors:

1, 2, 5 years

Replace generators:

10 years

Recommended

Battery replacement:

Every 2 years

Sensitivity testing of detectors:

Every 3 years

smoke/duct detector replacement:

Every 10 years

Clean Agent

Clean Agent Suppression Systems protect high dollar mission critical assets. A fire hazard would create havoc and substantial business interruption. It is crucial to inspect these systems and ensure optimal performance of the fire protection system.

Required

Agent quantity and pressure:

Every 6 months

Functionality testing:

Annually

Sensitivity testing on detectors:

Semi-Annually

Test for required cleaning (NFPA 96):

Every 1, 2, and 5 years

Inspect enclosure for dramatic changes in leakage:

Annually

Test discharge hoses, check valves, change initiators:

Every 5 years

Change out CGA (compressed gas actuator):

Every 10 years

Recommended

Battery replacement recommended:

Every 2 years

Sensitivity testing of detectors:

Every 3 years

Smoke/duct detector replacement:

Every 10 years

Backflow Preventers

Backflow preventers are required to be inspected and tested to prevent the contamination of our drinking water supply. Additionally, water must flow forward to provide the water necessary for the fire protection system. Thus, it is critical to ensure these devices are working properly and as such most Jurisdictions track compliance directly.

Required

Reduced pressure backflow relief port:

Weekly

Full forward flow test:

Annually

Fire Pumps

All sprinkler systems are dependant upon having the proper pressure to supply the system. Fire pumps are installed to increase the source pressure and ensure the system is fed properly. So testing and inspecting your fire pump is critical to the entire fire protection system. Without it, your lives and property are at stake.

Required

Fire pump casing relief valve:

Weekly

Fire pump pressure relief valve:

Weekly

Churn test (Diesel):

Weekly

Churn test (Electric):

Weekly

Full fire pump test and inspection:

Annually

Fire Hydrant

Fire hydrants are an important fire protection measure which provide firefighters access to water during an emergency. These devices should be regularly tested and inspected to ensure water is available during an emergency.

Required

Flow test:

Annually

Exposed piping inspection:

Annually

Flow test on exposed & undergroud piping:

Every 5 years

Stand Pipes

A standpipe is a rigid water pipe building into multi-story buildings in a vertical position or bridges in a horizontal position. The standpipe has connections for hoses, allowing manual application of water to a fire. Within the context of a building or bridge, a standpipe serves the same purpose as a fire hydrant.

Required

Standpipe system inspection:

Annually

Standpipe full flow test:

Every 5 Years

Hydrostatic test of manual and semi-automatic dry standpipes:

Every 5 Years

Fire Hose

A building fire hose is connected to a standpipe system and allows for a manual application of water to a fire. Recently, fire hoses have been removed to deter the public from fighting fires and encourage their prompt evacuation. A professional firefigher will carry their own hose to the standpipe connection and fight the fire.

Required

Inspect hose connections, hose racks, hose valves position and operating test

Annually

Hydrostatic testing of cylinder, Replace cartridge, Regulator test of wet chemical containers, hose assemblies:

Every 12 Years

Within initial 5 years and every 3 years thereafter

Test hose connections (full flow)

Test hose rack pressure reducing valves (full flow)

Internal Pipe

The purpose of this inspection is to check for the presence of sufficient corrosion or foreign material capable of obstructing sprinklers and rendering the system ineffective in the event of a fire. These internal inspections are especially critical for dry-pipe and preaction sprinkler systems.

Required

Functional Test, Change Fusible Links, Test for required cleaning (NFPA 96):

Semi-Annually

Hydrostatic testing of cylinder, Replace cartridge, Regulator test of wet chemical containers, hose assemblies:

Every 12 Years

Fire & Smoke Dampers

Fire & Smoke Dampers play a vital role in your facilities fire protection plan. They prevent the flow of toxic smoke and fumes throughout the facility by creating isolated compartments. Typically, these devices are located out of sight which means blockages or failures are difficult to detect. It is therefore vitally important to ensure these devices are inspected on a regular schedule.

Required

Functional Test:

One year after Installation

Functional Test:

Every 4 years thereafter

Obstruction Test:

Every 5 years

Recommended

Full functional and Obstruction Test:

Annually

Fire Doors

Fire Doors play a vital role in your facilities fire protection plan. Like fire and smoke dampers, they prevent the flow of toxic smoke and fumes throughout the facility by creating isolated compartments. These devices hide in plain sight and are plagued with DIY modifications, blockage, and code violations. It is critically important to make sure your doors are regularly inspected for compliance.

Required Anually

- The door frame, hinges, hadware, and non-combustible threshold are secured, aligned and in working order

- No open holes or breaks exist in surfaces of either the door or the frame

- Glazing, vision light frames, and glazing pads are intact and securely fastened in place, if so equipped

- No parts are missing or broken

- Door clearances at the door edge to the frame, on the pull side of the door, do not exceed the recommended clearances

- Floor space on both sides of the opening is clear of obstructions and door leaves open fully and close freely

- If a coordinator is installed, the inactive leaf closes before the active leaf

- Auxillary hardware items that interfere or prohibit operation are not installed on the door frame

- The self closing device is operational, that is, the active door completely closes when operated from the full position

- Latching hardware operates and secures the door when it is in the closed position

- No field modifications to the door assembly have been performed that void the label

- Gasketing and edge seals, where required, are inspected to verify their presence and integrity

Do you receive online inspections?

Get your Online ReportsSee the benefits of Online Inspection Reports.

View a sample reportAt Your Service

For inspection questions or to speak to inspection management, please contact us at 1-937-572-9651 or click here to send an email to our team.

At Your Service

For more details and a free VSP cost analysis of your inspection needs, please contact us at 1-937-657-7643 or click here to send an email to our team.

© 2024 A1 Sprinkler & Systems Integration. All rights reserved.